Big data is information having different formats, being collected from several various sources. The information that is being collected holds crucial importance for organizations as it helps businesses improve decision-making. According to a survey, big data market is estimated to achieve a market value of $1.1B by 2019. Big data analytics is being leveraged by organizations, and the ones that have not yet started off with the same are going through big data use cases to understand the statistical benefits of having the technology in their organization.

1. Supply chain management

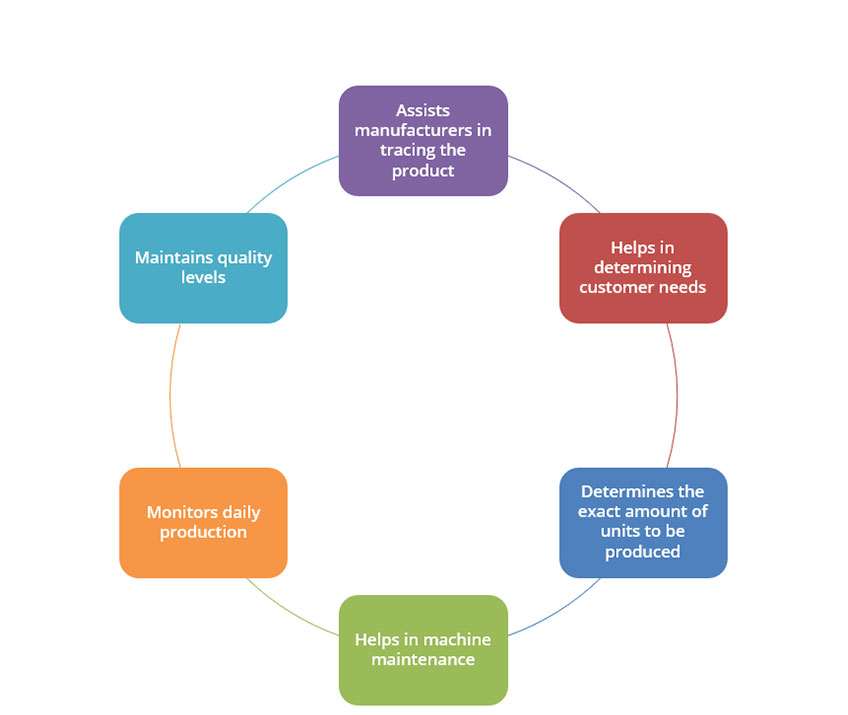

Big data provides manufacturers the ability to track the exact location of their products. This ability to track is one of the primary features that have been available for the manufacturers. Traceability is essential as often several products that have been released by manufacturers are lost and are difficult to trace. The coordinates of a parcel can be set up by using barcode scanners and radio frequency transmission devices. These devices transmit the location of the product, pinpointing where it is at a given point in time.

Determining what the customers need is one of the pain points when organizations want to forecast the current market trends. Big data helps here as it predicts the demands of the customers and also assists in providing the timings of when they want the product delivered. This forecasting can be done when companies refer to their supply chain and can help an organization in `improving the profitability and workforce.

2. Production management

Once the companies have determined what the market needs are, the same analytics can also assist organizations in determining the volume of products that are required in the market. Earlier when big data analytics did not exist, companies used to rely on human estimates that often led to either the product being developed in excess or less. This technique was rendered useless as it cannot be relied upon. With big data analytics, organizations get intuitive insights based on the information collected and analyzed.

3. Machine maintenance

When an organization is manufacturing anything, it plans to maintain its machinery; starting from how the machine is currently operating to what upgrades are essential for them to keep running efficiently. Using sensors, information can continuously be collected from these machines. The data gathered from devices helps organizations in determining when and how intense maintenance is required by a specific machine. Big data analytics can help manufacturers in keeping track of their machines by continually analyzing and focusing on how to improve the efficiency of devices.

4. Daily production

For an organization to operate efficiently, they need to monitor their everyday activities and monitor how useful are their production capabilities and how their day-to-day business is performing financially. Big data analytics can assist manufacturing companies in doing so by providing them intuitive insights from the information that is being collected from various sources. These sources can be their operational machines, databases keeping a log of the number of units produced, and employee records. This information can help companies in making decisions related to making changes that can be profitable for the organizations.

5. Quality Assessment

For a manufacturing unit, quality maintenance is a priority, as the units manufactured by an organization need to be of top quality. Big data analytics can be useful here too as it provides crucial information about any fluctuations in the process of the development process.

As manufacturing is transforming with the help of technologies, businesses realize the need to leverage these innovations in their workplace. Apart from being helpful to organizations in tracing and forecasting the requirements of the market, big data analytics also helps companies in keeping up with quality metrics and standards. This ensures that for the products developed by an individual manufacturer, the quality is intact and there is an increase in the organization’s profitability.